Initially we dove into the project with what looked very much like our finished product. However, we briefly experimented with different designs, ultimately using our final design as it was the quickest and easiest to build.

This is our initial design. A track would move marbles to a power track that would sense the reflected light and move to the correct bin. We quickly discovered that this would take way too long, and thus we quickly forgot about it.

This was thought up to address the speed issues, using pistons to force the marble to roll off at the correct place. We figured this would work fastest so we prototyped this. We quickly discovered that our light bounce off idea doesn't work at all, so we quickly moved on and forgot this idea, as we needed a more creative solution to filter the wood and metal.

Here we employed the gate idea, which was only high enough to admit the wood and metal marbles, which were later sorted via a magnet. However, it was much much too slow (took about 4 minutes for 15 marbles) and the marble would frequently not fall correctly on the sensing cart, the idea was quickly changed to remove the cart, using the "moving bins" system that Cody pioneered.

Here is our last design, including the last's track design, with the color sensor on the track and the bins moving. We were able to get the time to under two minutes, but marbles would frequently get stuck and fall into the wrong cart. This was later fixed by adding another piston and moving the color sensor, a simple fix that cost us some time.

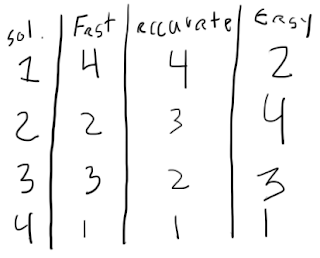

Decision Matrix

Here is our DM, with the fields "Fast", relating to how fast we could process 15 marbles, "Accurate", how many marbles went into their correct bins, and "Easy", how easy it would be to make this design. At the time we thought that design 4 won all these categories, but we later discovered that design 2 would have been the easiest to build.

Final Design

This is an overview of our design modeled in Blender. you can see the moving cart system as well as the added piston (Large blocks signify pistons, small ones indicate our color sensing equipment). Nothing much to say here, other then this design proved to be accurate and fast, and quite simple (Although it take much tinkering to make it work correctly).

The added piston removes the sensing from the marble gate, as multiple marbles could get caught in there at a time. This made it much more accurate, and stopped multiple balls from going on the same cycle. We also added a second compressor, which helped a lot as the design took up a top of compressed air.

We accomplished our objectives very well, in my opinion. We had 15 marbles sorted in less then two minutes, and we could cut down that amount drastically via fine tuning, but we did not have enough time to do this. Our solution changed little from our first construction, mostly fine tuning, and changing the cart to a set of bins, for this took much less time and came with its own set of challenges. Additionally, changing the light sensor to measure the amount of light that passes through the ball as opposed to bounces off the ball made it much more accurate, although it bounce off had worked we could have differentiated the marbles only via a light sensor, not with a magnet. Our project very neatly fulfilled the problem statement, as we accomplished all the goals and did so quite elegantly. Although some other designs would have beaten us time wise if given enough time to work out the kinks, ours prevailed on simplicity and ease to build. I learned how to iterate our designs and pull from other people, then adjust these ideas to form new ways to accomplish a task. If I were working alone I doubt that the project would have ended as it did, most notably the moving bins idea from Cody or the marble gate from David. The purpose of this exercise was to learn to design a product, then make it. We did just this, although the project ended up to be designed rather organically without any sort of review session, more “This is an issue, and this is how I think we can fix it”.

Achievement wise I would suggest one fro not using pneumatics (for those parts were in short supply), along with general "uses least parts", and especially one for using few solenoids, for those were rare. Other then that no part became rare that could not be worked around.

"Story" is the split between expectation and outcome. Great job telling the "story" of your iterative process of improving your design with your sketches. They're not pretty, but they work with your text and sequencing to paint a picture of what occured.

ReplyDeleteI'm very impressed to see you've modeled your solution in Blender. Being that Blender is Freeware (as are tools that could use it's content like the UDK and Unity), I'm interested in exploring this tool. I've actually installed it on one or two of our class laptops. Let me know if you'd like to try it out on your machine.

With your decision matrix, make sure you label your designs by name rather than just number. This will help a person that is unfamiliar with your project and decision making progress understand your evaluation.

Also, consider how you can improve the "readability" of your post. How could you make your write up more efficient and effective?

Keep in mind you're preparing to work on great projects. You're going to have to sell your vision to people that may be sceptical or interested in their own agendas!